You can also utilize common household products to develop this early-stage design. Above all, work with an item growth company that provides professional support throughout the entire process. They will ensure you are adhering to the right steps at the correct time and will certainly be there to respond to any type of questions in the process. This includes a pre-production, high-fidelity prototype and in-depth specs the manufacturer will certainly need to start mass production. Alpha growth and beta testing particularly will provide you several models to review. You can think about alpha testing as one of the most simple of all prototypes.

Manufacture Phase Manufacturing Prototyping

Throughout the alpha screening stage, you will certainly conduct a threat evaluation, answering concerns such as whether the products are inexpensive and lasting. Your goal is to determine any kind of dangers to product advancement, your supply chain, and profitability. When you have a brand-new item idea, you need to understand if it is feasible before you can transfer to the next phase. This evidence of principle phase includes a significant amount of research study, as well as your very first drawings. A development team or engineering team is trying to find information to determine whether their concept is technically practical and if purchasers will locate the item appealing and beneficial sufficient to acquire. Once you have a draft of your item, you can utilize a software application device to develop a 3D version of your product.

Create A Production-ready Prototype

Prototypes function as concrete versions so investors can see what the product should resemble. When done correctly, they can persuade stakeholders to sustain the item. Models also enable individuals and clients to see truth potential of your item. Through prototyping, item managers can examine different products and manufacturing approaches they think would be best for the item.

Wagestream Design Limelight: Jamie Potter, Engineering Manager

It is generated with the intent of the end product remedy yet may not be generated by the final production procedure, products, or tooling. It is totally practical, and the look looks just like a completed item. Engineers verify the kind, fit, and function of the layout prior to financial investments are made in tooling, machinery, and quality checks. Concept illustration prototyping is where the item concept fulfills its first test. It is when you relocate the item concept onto paper or a computer system.

High-fidelity prototypes that carefully match the final designated item can be created. User testing commonly highlights unexpected problems with the layout and can provide valuable understandings to improve the top quality of the product. A pre-production prototype is the final model before manufacturing takes place.

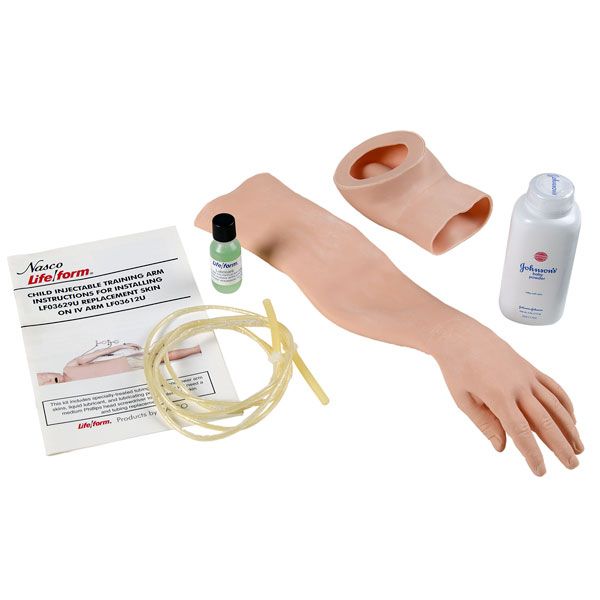

Environmental tests might also be needed to make sure the product will work in its designated setting without too much corrosion or general ecological deterioration. The task scope have to be specified before beginning any kind of new item growth trip. Generally, the cpr manikin job range is established by the customer or created with the end user or end function in mind.

Swimwear Brand Arena Achieves Faster, More Sustainable Prototyping with Dassault Systèmes' 3DEXPERIENCE Works - Dassault Systèmes

Swimwear Brand Arena Achieves Faster, More Sustainable Prototyping with Dassault Systèmes' 3DEXPERIENCE Works.

Posted: Wed, 14 Feb 2024 08:00:00 GMT [source]

For example, allow's claim you're setting up an automobile rental platform and you're looking to test its functionality. If you are trying to begin a company with a brand-new, exclusive item-- or develop new products for your existing company-- one of one of the most important actions is to create a product model. The manufacture stage model is the last validation check before mass production of the item. The initial off-the-line items will certainly be user-tested under real-world applications in the field. Select consumers offer responses concerning the integrity and practical efficiency of the item. The item assembly process is also optimized and evaluated throughout this phase with the help of the QC or quality control standard procedure.

The project extent is typically well-defined, with clear deliverables that help keep stakeholders aligned and prevent range creep. A distinct scope needs to consist of the relevant style standards, market regulations, efficiency needs, overall product dimensions, and assembly needs. Consisting of these vital factors in the scope helps in reducing the danger of needing to transform the trajectory of the style entirely.

Numerous prototypes of these aids can be created and tested to see what works and what doesn't. This process will ensure there are fewer difficulties when ramping up to full-blown manufacture. Prototyping during the layout phase includes specific components or subassemblies to examine if components can be set up, systems can operate as anticipated and can user interface properly with existing devices.

CPR Depot

340 Croft Dr, Tecumseh, ON N8N 2L9, Canada

+15199462222